With the continuous expansion and development of power systems, the operation and maintenance of distribution networks face numerous challenges. Traditional manual inspection methods are inefficient and struggle to meet the growing demands of distribution network maintenance. In recent years, the rapid advancement of surveying drone technology has provided new solutions to these issues. Surveying drones, leveraging their flexibility, mobility, and intelligent capabilities, show great potential in the field of distribution network operation and maintenance. By integrating surveying UAV technology with communication systems, a maintenance management system based on drone communication can significantly enhance the efficiency and quality of distribution network inspections. This paper designs and implements such a system, focusing on its architecture, data acquisition, analysis, and task management modules, supported by experimental validation.

The current state of distribution network operation and maintenance management is a critical aspect of ensuring the safety, stability, and reliability of power systems. However, it is plagued by inefficiencies, such as the low productivity of manual inspections, the diversity and wide distribution of equipment, and the high demands on personnel expertise. Additionally, the planning, scheduling, execution, and management of maintenance tasks lack unified and efficient信息化手段, making it difficult to adapt to increasing operational needs. To address these challenges, we have developed a maintenance management system utilizing surveying drones. This system capitalizes on the agility and intelligence of surveying UAVs to enable efficient inspection and condition monitoring of distribution network assets. Equipped with high-definition cameras, infrared thermal imagers, and other instruments, these drones capture visible light images and thermal data, transmitting them in real-time to a ground control center via onboard communication devices for intelligent analysis and fault diagnosis.

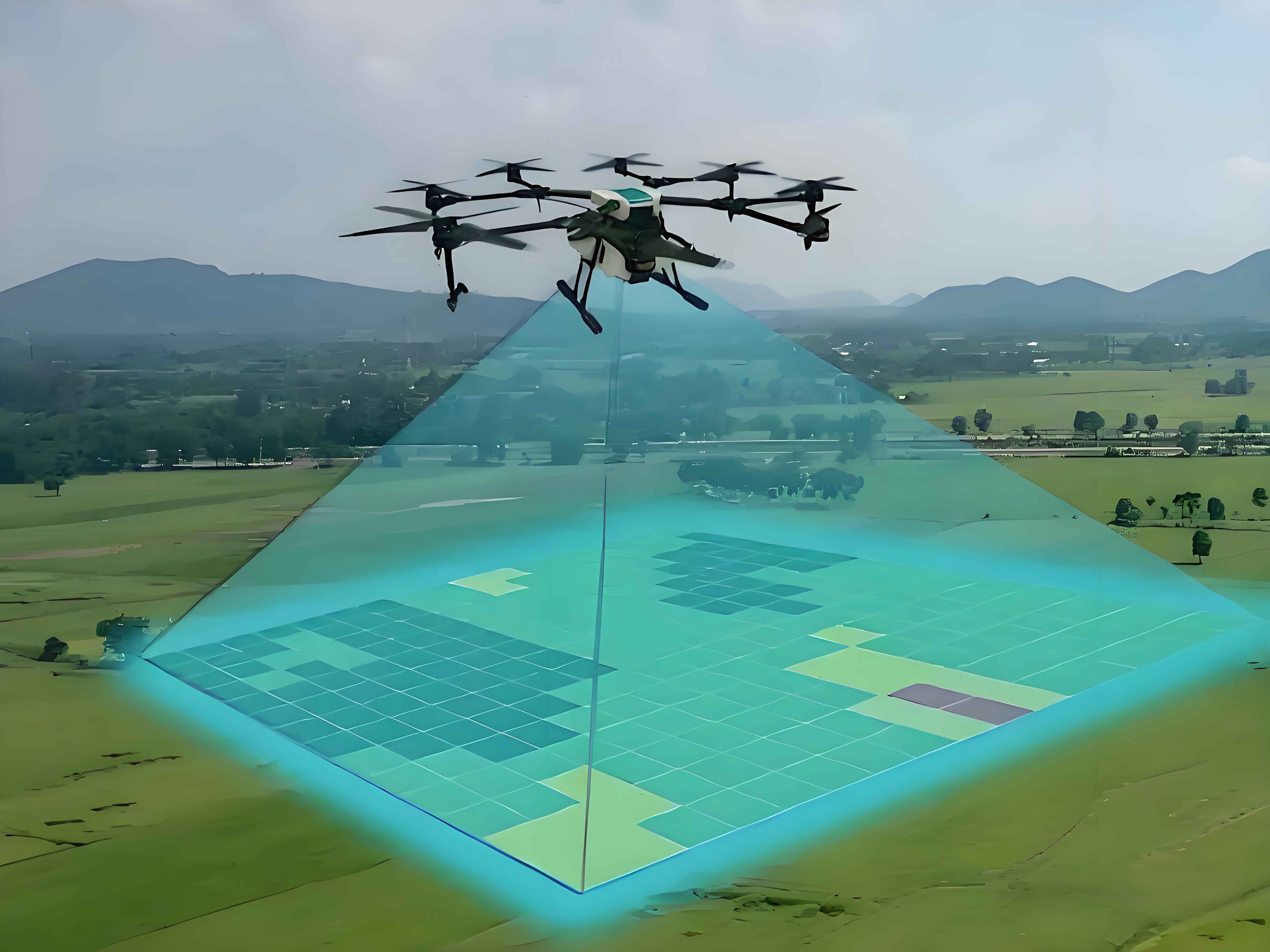

The architecture of the surveying drone-based distribution network maintenance management system is modular, enabling intelligent and automated monitoring, fault diagnosis, and task management. Surveying UAVs are deployed with multi-source sensors, including high-resolution cameras and infrared thermal imagers, to perform autonomous flight inspections and collect multi-dimensional data on key components like distribution lines, poles, insulators, and transformers. The inspection data are transmitted in real-time to the ground control center using onboard 5G communication modules. Deep learning algorithms are then applied for intelligent analysis, allowing for precise segmentation of device components and diagnosis of up to 10 typical defects, such as insulator contamination and arrester damage, through transfer learning models. This generates health assessment reports, which trigger the automatic generation of maintenance tasks optimized by intelligent scheduling algorithms. Field operations are conducted via mobile terminals, where surveying drones and personnel collaborate to address defects. The system also adapts to complex scenarios, such as adjusting flight parameters and optimizing trajectories in adverse weather conditions.

The data acquisition and communication module is a core component of the surveying drone-based system. It consists of a data acquisition unit and a communication unit. In the data acquisition unit, devices like the DJI Zenmuse P1 full-frame camera and Zenmuse H20T multi-sensor gimbal are utilized. The P1 camera features a 45-megapixel full-frame sensor, capturing high-resolution visible light images with a resolution of 8192×5460 pixels. The H20T integrates a 12-megapixel wide-angle camera, a 40-megapixel zoom camera, a 640×512 infrared thermal imager, and a 1200m laser rangefinder, enabling the collection of multi-spectral and multi-perspective image data. Through multi-sensor fusion technology, real-time registration of visible light, thermal infrared, and laser point cloud data is achieved with an accuracy of up to 0.05m, providing high-quality data sources for subsequent analysis. Additionally, a high-precision positioning unit based on RTK technology is integrated, using dual-frequency GPS receivers and ground base station data to achieve centimeter-level positioning accuracy (horizontal accuracy better than 1cm, vertical accuracy better than 2cm), ensuring spatial precision in data collection.

In the communication unit, 5G technology is employed, with devices like the Huawei 5G CPE Pro 2 router offering theoretical peak rates of up to 1.65 Gbps and end-to-end latency as low as 10ms. By deploying multiple 5G micro-base stations and combining them with surveying UAV ad-hoc network technology, a high-speed, low-latency, and reliable air-ground collaborative communication network is established, facilitating real-time data transmission between drones and the ground control center. This enhances the overall efficiency of the surveying drone system.

The data analysis and diagnosis module is another critical part of the surveying UAV-based maintenance system, responsible for intelligently analyzing and diagnosing faults from the multi-source heterogeneous data transmitted by the acquisition module. This module employs deep learning algorithms, including DeepLabV3+ for image segmentation and ResNet-50 for fault diagnosis via transfer learning. The DeepLabV3+ algorithm accurately segments key components of distribution equipment, such as insulators and arresters, with a segmentation accuracy exceeding 95%. The ResNet-50 algorithm, pre-trained on large-scale datasets of distribution equipment faults, rapidly diagnoses 10 common fault types, including insulator contamination and conductor foreign objects, achieving a diagnostic accuracy of 98%.

In terms of hardware, the module utilizes the NVIDIA Jetson AGX Xavier embedded AI computing platform, which features 512 CUDA cores in a Volta architecture GPU and 8 ARMv8.2 64-bit CPU cores, delivering exceptional performance and energy efficiency. It is equipped with 512GB of solid-state storage and 32GB of LPDDR4x memory, providing ample storage and operational memory. On the software side, it is developed based on the TensorFlow 2.0 deep learning framework and OpenCV 4.0 computer vision library, with Python 3.7 as the primary programming language. To quantify the health status of distribution equipment, a weighted fusion-based health index evaluation model is proposed. Let \( w_i \) represent the severity weight of the \( i \)-th fault type, and \( p_i \) denote its occurrence probability as predicted by the ResNet-50 model. The health index \( H \) is calculated as follows:

$$ H = 1 – \sum_{i=1}^{n} w_i p_i $$

where \( n \) is the number of fault types considered. The weights \( w_i \) can be determined based on expert experience, and \( p_i \) is derived from the fault diagnosis model. This health index quantitatively reflects the overall health level of distribution equipment, aiding in maintenance decision-making for surveying drone operations.

The maintenance task management module is an integral component of the surveying UAV-based system, focusing on automatically generating and optimizing maintenance tasks based on the output of the analysis module, while monitoring and managing task execution in real-time. Software-wise, it is developed on the Microsoft .NET Framework 4.7 platform using C# programming language, with a user-friendly interface implemented via DevExpress 19.2 WinForms controls. It integrates APIs like Baidu Maps for geographic visualization and Google OR-Tools for solving optimization problems in task scheduling. Hardware-wise, it is deployed on a high-end workstation featuring an Intel Xeon W-2245 CPU (8 cores, 3.9GHz), 128GB DDR4 ECC memory, 1TB PCIe NVMe SSD, and an NVIDIA Quadro RTX 4000 GPU (8GB GDDR6 VRAM), ensuring sufficient computational resources.

When faults or anomalies are detected by the analysis module, the task management module automatically generates maintenance tasks, specifying attributes such as task type, priority, execution time window, and required resources. It considers factors like equipment importance, fault severity, geographic location, and environmental conditions to solve vehicle routing and resource-constrained project scheduling problems, yielding a globally optimal task schedule that minimizes completion time and maximizes resource utilization. Tasks are presented to dispatchers through a human-machine interface, where adjustments and confirmations can be made. Once confirmed, tasks are automatically dispatched via 5G communication to field personnel and surveying drones. Personnel use mobile terminals like tablets to receive tasks and report progress, while drones execute flights and maintenance actions autonomously based on task parameters. During execution, the module tracks personnel locations and drone trajectories in real-time, dynamically adjusting task plans in response to unforeseen events through interaction with the analysis module.

To evaluate the performance of the surveying drone-based distribution network maintenance management system, an experiment was conducted on a 10kV distribution line in a suburban area covering approximately 50 square kilometers, including 100 poles and 5 distribution transformers. A comparative experiment was designed, with the area divided into two parts: Zone A used the proposed surveying UAV system, employing a DJI Matrice 300 RTK drone equipped with Zenmuse P1 and H20T devices and 5G communication for real-time data transmission; Zone B used traditional manual inspection combined with vehicle-mounted mobile terminals, where inspectors carried handheld infrared thermal imagers and high-power telescopes, relying on 4G networks for data transfer. The experiment lasted 31 days, from July 1 to July 31, 2024, and evaluated key metrics such as inspection efficiency, fault detection rate, diagnostic accuracy, response time, and system reliability.

The results demonstrated the superiority of the surveying drone system. For instance, inspection efficiency was measured as the number of devices inspected per day, with the drone system achieving an average of 40 devices, double that of traditional methods. The fault detection rate reached 95.8%, a 15.3 percentage point improvement, attributed to the high-resolution cameras and multi-sensor gimbals on the surveying UAVs. Diagnostic accuracy, driven by deep learning algorithms, was 98.2%, an 8.7% increase over manual diagnosis. Response time, defined as the average time from fault discovery to technician arrival, was reduced to 22 minutes with the drone system, 53 minutes shorter than traditional approaches, highlighting the benefits of 5G communication and intelligent scheduling. System reliability, measured as the proportion of normal operation time, reached 99.5%, slightly higher than traditional methods. The following table summarizes the comparative results:

| Metric | Surveying Drone System | Traditional Method | Improvement |

|---|---|---|---|

| Inspection Efficiency (devices/day) | 40 | 20 | 100% |

| Fault Detection Rate (%) | 95.8 | 80.5 | 15.3 pp |

| Diagnostic Accuracy (%) | 98.2 | 89.5 | 8.7 pp |

| Response Time (minutes) | 22 | 75 | 53 minutes faster |

| System Reliability (%) | 99.5 | 98.0 | 1.5 pp |

These results confirm that the surveying drone-based system outperforms traditional methods across multiple key indicators, emphasizing its advantages in efficiency, accuracy, and real-time performance. The integration of surveying UAVs with advanced communication and AI technologies enables a more robust maintenance framework.

In addition to the primary metrics, further analysis was conducted to understand the system’s scalability and adaptability. For example, the health index model was applied to assess the overall condition of equipment in Zone A, with results showing a strong correlation between low health indices and actual fault occurrences. The formula for health index, as mentioned earlier, is:

$$ H = 1 – \sum_{i=1}^{n} w_i p_i $$

where \( n = 10 \) for the fault types considered. In practical terms, this allows for proactive maintenance scheduling based on predictive analytics, reducing downtime and costs. Moreover, the communication performance of the surveying drone system was evaluated under various conditions, such as different weather scenarios. The latency \( L \) in data transmission can be modeled as a function of distance \( d \) and signal strength \( S \), approximated by:

$$ L = L_0 + k \cdot \frac{d}{S} $$

where \( L_0 \) is the base latency (e.g., 10ms for 5G), and \( k \) is a constant factor. Experimental data showed that even in adverse conditions, the surveying UAV system maintained latency below 20ms, ensuring reliable real-time operations.

Looking ahead, the future of surveying drone-based maintenance systems holds promise with advancements in artificial intelligence and communication technologies. We anticipate higher precision in fault prediction and autonomous decision-making capabilities. Integration with emerging technologies like edge computing and digital twins could further enhance the intelligence and automation of distribution network maintenance, laying the foundation for safer, more reliable, and efficient smart grids. For instance, edge computing could enable real-time data processing on the surveying drones themselves, reducing dependency on central servers and improving response times. Digital twins would allow for virtual simulations of the distribution network, enabling predictive maintenance and scenario testing without physical interventions.

In conclusion, the surveying drone-based distribution network maintenance management system represents a significant leap forward in addressing the challenges of modern power systems. By leveraging the flexibility of surveying UAVs, the speed of 5G communication, and the power of deep learning, it offers a comprehensive solution for intelligent inspection and fault diagnosis. The experimental results validate its effectiveness, and ongoing research aims to refine its capabilities for broader applications. As technology evolves, we expect this system to become a cornerstone of smart grid infrastructure, driving improvements in reliability and efficiency across the power distribution sector.